An alternative approach to single reeds.

by Gijs van Leeuwen

The most underrated, neglected and least understood

part of the single reed is the plane bottom.

Come again? Is there anything at all to understand about a flat plane?

Well, first of all it’s not plane, not really, nor flat, nor smooth, for that matter.

Not even right out of the box, and it gets worse.

Look for yourself:

Place a brand new reed on a super flat surface (e.g. a piece of aluminum profile) and look under the reed towards the light. With a lot of reeds, you might see that the tip and the heel touch the surface, the heart is elevated. This concave reed effectively closes the mouthpiece’s tip opening. It’s tricky to measure and every reed is different, but 0.2 mm is not uncommon for a Vandoren Bb clarinet reed, 0.4mm is not to be ruled out. With a Bb clarinet mouthpiece tip opening of about 1.0 mm, that is a staggering 20%-40%! On the other hand, I’ve seen Rico Reserve reeds that were 0.3 mm open! That might prove not too bad, as we will see below.

So: not plane.

Flat? Hardly.

Take a soft pencil, colour the complete bottom of the same reed, (don’t scratch the cane, colour it gently) and try to sand it gently (almost no pressure!) on a sand paper, e.g. grain 400, glued onto a piece of glass with double sided tape. You might see spots that become “clean” after some polishing, and spots that stay coloured, as you can see below with a Marca, d’Addario and Vandoren reed. Conclusion must be that the reed is not flat. You’ll need to sand for quite some time and with coarser sand paper to clean the complete surface.

Some of you are used to polishing your reeds, and the surface might feel a bit better and softer. But still, you will not be able to make the reed more plane or flat without completely ruining the reed, because you cannot put pressure on the tip of the reed. Besides, try to imagine what removing 0.2 mm of the reeds 0.2 mm tip would do to the reed.

Not flat. Smooth?

Follow the link for a short video

The milling machines that are commonly used to produce the reeds, are ripping away chips of the material at a high speed, leaving a surface that is far from smooth. Again, when you polish the bottom of the reed to make it smoother, you will definitely have the feeling that the surface does become less coarse.

However, when you’ve ever painted a piece of fresh untreated wood, you’ll know that polishing a coarse surface with sand paper grain 1000 will not work. You have to work your way up to 1000, through grain 80, 150, 240, 400 etc.

(And after the first layer of paint you feel you can start all over again.)

Why are plane, flat and smooth at all important?

Is not the shape of the vamp more essential, and the quality of the cane?

A mouthpiece is made with extreme CNC controlled tolerances of 1/100 of a mm. CNC reed machines theoretically could match the same precision.

Theoretically. We’ve analysed the bottom, but the facing can also easily show left/right tolerances of 0.05 mm for Vandoren and d’Addario, I’ve seen 3 Marca reeds even up to 0.17 and one as much as 0.20 mm in a box of 10 reeds. (Of course one can question the accuracy of these measurements, as we cannot trust the bottom of the reed).

Also, the fact that reeds are strength categorized from 1 to 5 after production, might say something about the production process.

Finding a really matching reed-mouthpiece combination is a lottery.

Of course, you’re used to it, you cope with it, you may work on balancing a given reeds, you try to hide its shortcomings, maybe even thinking they are your personal shortcomings. Or you just throw the reed away and hope the next is better.

Much of these sorrows and efforts are mainly the result of the reed’s bottom not being made accurately plane and flat. Thicker, wider or narrower blanks, new reed facings, filed or unfiled shoulder, organic cane production, a new mouthpiece or ligature etc. can not ever make up for a flawed base and inaccurate reed production methods.

The lack of smoothness of the reed (not the same as the the aforementioned lack of dimensional accuracy) also affects it’s playing qualities.

It determines the speed and depth with wich the moist can infiltrate the cane, as shown in the ink test in the video above. Since the enzymes in saliva break down the material, this is important for the reed’s longevity, resilience as well as the speed with wich it changes. It also determines how long you can play a new reed before it is completey wet and you have to put it away to dry. It determines the need of breaking in reeds.

Cane also alters under the influence of moist,

besides the degrading effect of enzymes.

The bottom will show an “emboss” of the mouthpiece window, the tip will become thicker, and may warp, we’ve all seen that happen.

Less commonly known, but may be even more important: The reed that is often already concave from the outset as stated above, will bend even more towards the mouthpiece, closing the tip opening and shortening the facing length of the reed/mouthpiece combination even more. The constant pressure of the embouchure towards the mouthpiece, however relaxed you try to play, is also nudging the wet reed in the same direction.

The results of the effective smaller tip opening and facing length are considerable: less possibilities for expression, voicing, dynamics, articulation. More struggle to get the beauty that’s in your head out in the open. More labour, less art.

What can be done?

Some tactics from easy to almost impossible (until now…)

- Wet your reeds with water. Where there is water, there can be no saliva, so no enzymes to break down the cane. Tackles only one of many problems, but it does help.

- Polish the bottom of a new reed. It will never ever become plane, you will not be able to repair the concave and/or bumpy “plane”, but it does help. Experiment with different grains of sandpaper, or even just “paper” Essential: stick the sand paper perfectly flat on sufficiently thick glass, perspex or similar, sand or polish with little pressure.

- Make your own reeds. Nowadays there are good reed copying machines that are not difficult to handle. Indeed, reed machines are not cheap, but in the long run they are. You could consider buying one with a bunch of friends and share the joy. Some 40 years ago, I learned to work with knifes and files. That wás difficult, time consuming with quite a flat learning curve, it took me years. Nowadays, you don’t need special skills, just patience, precision and the right tools. One reed takes 15 to 20 minutes in total, but in stages, in say seven days. It’s not a good idea trying to make a reed for this evening’s concert. Making the bottom of a blank perfectly flat and smooth is essential, but easy, when you know how to. It might take more time than making the vamp. Once the bottom is perfect, you’re more than half way towards a reed that lasts longer than you can imagine and will open artistic paths that you never could have dreamt to tread.

During my active years as a clarinetist, teacher and reedmaker (using a BKM IV reed copying machine ,alas out of production, someone should start building that machine again) I used 6 reeds a year. I sold my reeds to some of my pupils (amateurs) for €25 a piece, they used 2-3 reeds a year. A brand new reed could easily be played for half a rehearsal or concert.

At a single reed event in Utrecht, Netherlands, I hand built my first (and only) reed for baritone saxophone, only having a mouthpiece at hand, (no instrument, not even a neck), showed it to Henk van Twillert, and he played a Bach Suite in a concert an hour later on that same reed. No balancing or adapting to the player or mouthpiece was needed.

2014 Katowice, Poland, European Clarinet Congress: two hand built reeds for Alex Simu’s tenor clarinet, same result, used during a concert the same day. Alex is using mostly plastic reeds now, but sometimes plays my reed to know what it was like to play on a real cane reed.

In another experiment I cut 10mm of the tip of a brand new Vandoren reed, sanded and polished this new “blank” to perfection, and used another new Vandoren reed (not tried it, so I did not know if it was a good reed) as model to make a copy on the new blank. It proved to be a better reed than any reed in any Vandoren box.

This is not to show how good I was as a reed maker. It’s just to show the importance of being in control, especially of the bottom of the reed. It shows what a good reed machine is capable of.

It also shows that either the cane Vandoren uses is great, or cane quality does not matter that much…. and that Vandoren should do better. This leads to:

- Urge reed companies to do better. Good luck with that. I’m positive it can be done, where there’s a will, there’s a way, and I would be happy to help. But is there a will? Would better, longer lasting reeds not interfere with what seems to be (at least from my perspective) the current revenue model of Big Reed? (“The more they throw away, the more we sell”).

Of course, such a artisan Ligne extra spéciale professionelle supérieure bellissimo reed would be more expensive (read: less cheap), but the popular synthetic reeds are also not cheap.

Besides: are you happy now? How many reeds in a box are flat out disappointing, and how few make you fall in love again with your instrument, like before?

And how often is a prommising reed still prommising tomorrow?

- Regenerate and revive your reed by countering the tip-closing effect of moist and the flawed base. Double reed players do it all the time: They push the sides of a reed together to “open” the reed before an important solo. You do not see single reed players do that often. It does work, but for a short period of time only, because the reed stays wet and easily closes again. The traditional plane reed case is just not enought to stretch the reed. For this method to obtain a long lasting effect on single reeds, the tip should be bent beyond plane (so convex instead of concave) and stay that way until completely dried.

One difficulty of course is to do this in a controlled and repeatable way, sustainded until the reed in actually dry.

Another hurdle would be to decide what degree of convexity you need for a given reed, and over what vamp length this elevation should be reached, to compensate enough but not too much, while at the same time leaving the heel of the reed completely plane (well, actually, as “plane” as is was before….) to correspond with the mouthpiece’s table.

This is virtually impossible.

Until now.

Enter: WoodWindDesign’s new ReeGenerator.

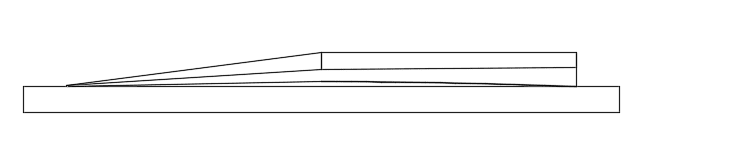

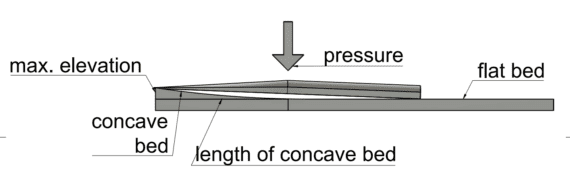

A patent pending reed case, that provides the musician with a partially flat, partially concave reed bed, lifting the reed’s tip and vamp in a controlled and repeatable manner.

The maximum tip elevation (in the drawing exaggererated for a clear picture) and the length and shape of the concave section of the reed bed can be varied. (in the drawing: a segment of a circle with a relatively large diameter).

Pressure with a rubber band, fixed at the spot of the arrow where concave and plane meet, will result in the reed following the plane as well as the concave section.

In this way, the dried, partially convex reed is conditioned and “opened up” for next use. The resilience is chalenged and has been reset, as it were. You might compare this with stretching your muscles after sport, to prepare for tomorrow.

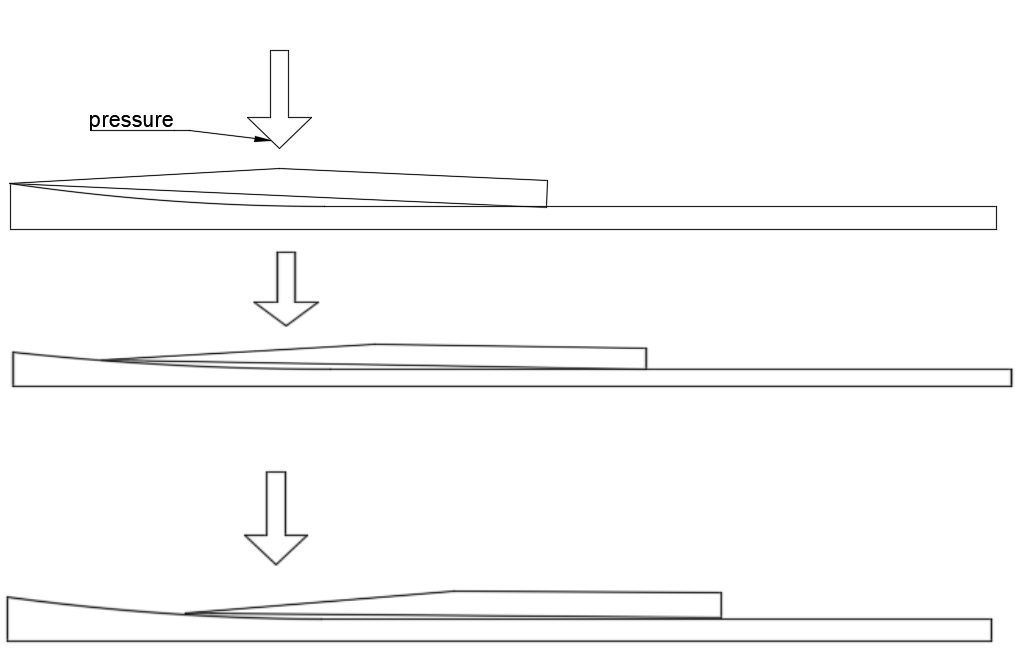

Pulling back the reed on a given reed bed while the pressure is still on the same spot, as shown above, will obviously result in smaller tip elevation, over a smaller vamp length. In this way one concave bed presents a lot of possibilities.

To be able to pull the reed back, the reed bed is of course longer than usual.

As stated before, the usual perfectly plane reed case is not stretching your reed at all. The resilience of the reed is just too strong. When using the ReeGenerator, pulling back the reed to about 10 mm from the rubber band will have the same result: nothing. The theoretically still present small concave part ( approximately 0.1 mm open) under the tip will have no influence whatsoever.

So even when this concept is totally not your cup of tea -or when you decided to make your own reeds, and you don’t really need it any more- the ReeGenerator is not an utterly worthless piece of equipment: Just use it as a normal flat bed reed case.

Experiments show, that an elevation of 0.4 mm, with a length of 30 mm (approximate vamp length) for a Bb clarinet reed, will result in a near straight dried reed. (Note that the tip elevation in the drawings is unrealistically large, 0.4 mm would be invisible.) Of course the reed does not stay completely straight once you start playing, but it is a logical starting point for experiments.

So many questions:

- The dried reed will be more open than before, but how much?

- How much of the extra opening will stay when the reed is played?

- For how long?

- Would one treatment be enough for a week?

- Or is permanent storage of the reeds in the ReeGenerator needed?

- Does an old reed need more elevation than a new one because it is more closed?

- Or does it require less, because the material has lost much of the “spring” force?

- Is it usefull to treat the reeds a few times before even starting to play?

- Which concave would be ideal for you? 0.4 x 30 mm? 0.6 x 30 mm?

Answers

can only be obtained by your personal experiment.

I cannot tell, because your saliva and embouchure may be less aggressive than mine, but also because tinnitus, as well as designing and making cool stuff for musicians, is making it difficult for me to play and experiment as much as I would like.

And last but not least: When I’m playing, I have no wish whatsoever to do so with commercially produced reeds. My reeds start straight and are prepared to stay that way. That’s enough for me…

To be able for you to decide what’s best for you, I designed 3 testcases with 6 different tubular concave sections each.

(Of course there are other possibilities to shape a concave, apart from tubular, but let’s not make it more complicated than it already is, shall we?).

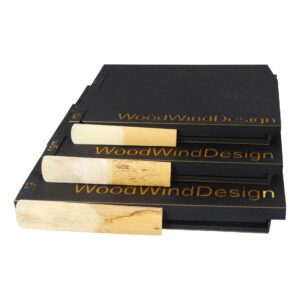

Small, for Bb and Eb clarinet, soprano and sopranino saxophone

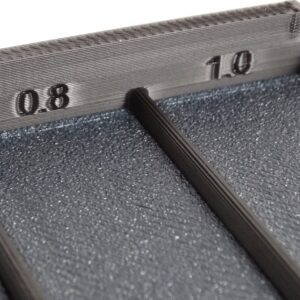

0.4; 0.5; 0.6; 0.7; 0.8 and 1.0 mm (max. tip elevation) x 30 mm (concave length= approximate length of the mouthpiece’s facing)

Medium, for alto and bass clarinet, alto and tenor saxophone.

0.4; 0.5; 0.6; 0.7; 0.8 and 1.0 mm x 40 mm

Large, for contrabass clarinet, baritone and bass saxophone.

0.4; 0.5; 0.6; 0.7; 0.8 and 1.0 mm x 50 mm

These three are specifically meant to be test cases so you can determine what is best for you, your brand of reeds, your mouthpiece, your style, your embouchure.

When you’ve decided what works best for you, (or when you want make a big leap forward) 6 and 12 reed cases with one specific concave geometry can be ordered and will be custom made.

Theoretically an endless variety of different ReeGenerators is possible, I can imagine that in a year only a few variations will survive, but that’s up to you.

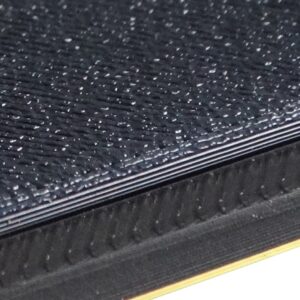

The design of these cases

-as you might expect when you know WoodWindDesign’s ultra light and compact carbon instrument stands for wood and brass- is as small and light as possible, and with an attractive, futuristic and minimalistic design, black with gold accents. It closes with magnets.

The surface of the reed bed has a shallow profile, so the moist escapes easily, and the design of the cases is very open, so the reeds drie fast.

Of course I also designed flat bed reed cases, no magic there, just old fashioned protection, but in the same minimalistic black/gold jacket. Available in Small, Medium and Large, 6 and 12 reeds.

On top of all that, there will be the possibility to have your ReeGenerator or reed case personalised, with your name, initials, orchestra, instrument, nick name or whatever.

Humidity control

is something I personally do not believe in. It simply does not seem logical to me. When you use water to wet the reed (water is thinner, so faster than saliva, besides being less aggressive) I would think that the humidity of the cane will soon be on it’s maximum, given the age of the reed. Inside your mouth I expect about 100% humidity.

But then again, I may be wrong. I live in the Netherlands with a moderate maritime climate (still…), so I’ve never had the urge to experiment with humidity control. Might also have something to do with the quality of my reeds, but I have no arguments to support that claim. Convince me that I’m wrong, and I might consider making humidity controlled ReeGenerators.

Meanwhile, when you still would like to have the humidity controlled NOW with your WoodWindDesign reed case or ReeGenerator, I suggest you place it in a plastic zipper bag with a Boveda sachet of your preference.

That’s all for now folks,

thanks for reading this to the end, I’ve done my bit, it’s your turn to experiment now.

Visit woodwinddesign.com for ordering, or mail your questions to info@woodwinddesign.nl

Cheers!

Gijs van Leeuwen

March 2024